Steel is one of the most versatile materials on the planet, and National Material Company, a leading American metal processor, knows it better than most. In this blog, we’ll explore the unique properties that make steel a durable, strong, and adaptable material for a wide range of applications. From construction to transportation to everyday household items, steel has become an integral part of our lives.

Join us as we dive into the versatility of this material and why it continues to be a crucial component in various industries.

Strength and Durability

One of the most notable properties of steel is its strength and durability. Steel is known for its high tensile strength, which means it can withstand a lot of stress without breaking or deforming. This makes it ideal for use in construction, where it can be used to create buildings, bridges, and other structures that need to support a lot of weight and withstand harsh weather conditions.

Flexibility and Malleability

While steel is incredibly strong, it is also remarkably flexible and malleable. This means it can be shaped and molded into a variety of forms without losing its strength. This makes it ideal for use in manufacturing, where it can be used to create everything from car parts to household appliances.

Corrosion Resistance

Another important property of steel is its resistance to corrosion. Steel, when properly treated, is highly resistant to rust and other forms of corrosion, making it an ideal choice for various applications. For instance, steel coils can undergo a galvanizing process in a continuous galvanizing line, like the one available at National Galvanizing – a National Material partner company. This process involves applying a galvanized coating to the steel, which further enhances its corrosion resistance. Galvanized steel is widely used in automotive manufacturing, appliances, agricultural equipment, and other demanding applications where superior corrosion protection is essential.

Notably, galvanized steel body panels are highly sought after by automakers due to their exceptional corrosion protection. These panels enable automakers to offer corrosion-free performance for extended periods, often guaranteeing a decade or longer of rust-free operation.

Recyclability

Steel is also highly recyclable, which makes it an environmentally friendly choice. When steel products reach the end of their useful life, they can be recycled and used to create into new steel products, reducing the need for new steel production, and conserving natural resources.

Cost-Effectiveness

Finally, steel is a cost-effective, widely available material and is easy to manufacture. This makes it an affordable choice for a wide range of applications, from construction to manufacturing to consumer goods. American metal processors like NMC have the expertise to offer cost-effective solutions to their customers. By leveraging their knowledge of steel processing and manufacturing, they can produce high-quality products at competitive prices.

What are the types of steel and how is it determined?

Steel types are determined based on various factors, including their chemical composition, physical properties, and intended use. The main elements that determine the properties of steel are carbon, alloying elements, and impurities.

Carbon content is one of the primary factors that determine the properties of steel. Based on the amount of carbon present, steel can be classified as low-carbon steel (up to 0.3% carbon), medium-carbon steel (0.3-0.6% carbon), high-carbon steel (0.6-1.4% carbon), and ultra-high carbon steel (more than 1.4% carbon).

Alloying elements are added to steel to improve its strength, toughness, and other properties. Common alloying elements include nickel, chromium, manganese, molybdenum, and vanadium.

The intended use of steel also plays a role in determining its type. For example, structural steel is designed to be used in construction, while tool steel is designed for cutting and shaping tools.

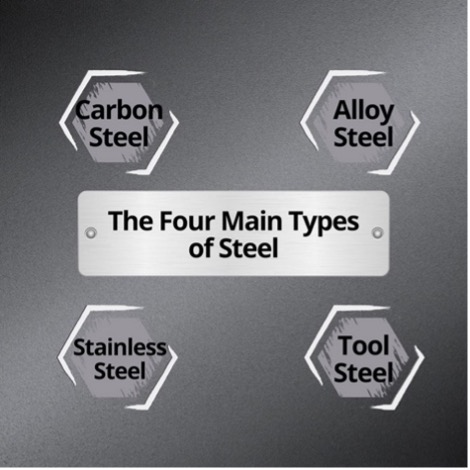

The Four Main Types of Steel

-

Carbon Steel

This is primarily made up of carbon and is commonly used in construction and manufacturing due to its strength and durability. It is often classified further based on the amount of carbon present: low carbon steel, medium carbon steel, and high carbon steel.

-

Alloy Steel

This contains other elements besides carbon, such as nickel, chromium, and manganese, which are added to improve its strength, toughness, and other properties. Alloy steel is often used in the construction, manufacturing, and automotive industries.

-

Stainless Steel

This is a type of steel that contains at least 10.5% chromium, which forms a protective layer on the surface that makes it highly resistant to corrosion. Stainless steel is commonly used in kitchen appliances, medical equipment, and chemical processing industries.

-

Tool Steel

This type of steel is designed to be used in the production of cutting and shaping tools such as drills, saw blades, and dies. It is often made with tungsten, vanadium, or other elements to enhance its hardness and resistance to wear and deformation.

Standardized Numbering Systems

Steel types can also be determined using standardized numbering systems known as the AISI/SAE. This system was developed by the Society of Automotive Engineers (SAE) and the American Iron and Steel Institute (AISI) to standardize the naming and classification of different types of steel.

The AISI/SAE Steel Numbering System uses a four-digit number to designate the chemical composition of the steel. The first two digits represent the alloying elements or steel group, while the last two digits represent the carbon content of the steel.

For example, the number “1018” represents a low carbon steel with 0.18% carbon content. The number “4140” represents a chromium-molybdenum alloy steel with 0.40% carbon content.

In addition to the four-digit designation, the AISI/SAE Steel Numbering System may also include a letter prefix to indicate the specific process used in the production of the steel. For example, the prefix “C” indicates that the steel has been cold worked, while the prefix “H” indicates that the steel has been hardened.

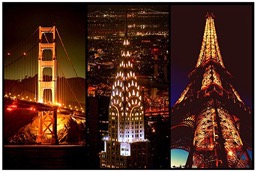

How Steel Help Build the World Today

The construction industry is the largest consumer of steel in the world. According to the World Steel Association, the construction sector accounted for around 50% of global steel demand in 2020. It is used extensively in the construction of buildings, bridges, highways, tunnels, and other infrastructure projects due to its strength, durability, and versatility.

Here are some examples of how steel is used in the construction industry:

-

Structural Steel

This is used in the construction of buildings and other structures due to its high strength and durability. It is commonly used for framing, columns, beams, and other load-bearing elements. Steel structures are ideal for high-rise buildings, bridges, and other structures that need to support heavy loads and withstand harsh weather conditions.

-

Reinforcing steel

Also known as rebar, this steel is used to reinforce concrete structures such as foundations, walls, and slabs. Steel rebar is inserted into the wet concrete before it sets to provide additional strength and stability to the structure.

-

Roofing and Cladding

Steel roofing and cladding are popular choices for commercial and industrial buildings due to their durability and low maintenance requirements. Steel roofing can be designed in a variety of styles, and it is ideal for buildings with large roofs, such as warehouses and factories.

-

Facades

Steel is often used for building facades due to its flexibility and aesthetic appeal. Steel facades can be designed in a variety of shapes and sizes, and they can be customized with a range of finishes and colors.

-

Bridges

Steel is an ideal material for bridge construction due to its strength and durability. Steel bridges can span long distances and withstand heavy loads, making them essential for transportation infrastructure.

-

Modular Construction

Steel is increasingly being used in modular construction, where building components are prefabricated offsite and assembled on-site. This method of construction is faster and more cost-effective than traditional construction methods.

The second-largest consumer of steel today is the automotive industry — accounting for around 16% of global steel demand in 2020. Steel is used in the manufacturing of cars and trucks for their bodies, frames, and engine components due to its strength, formability, and cost-effectiveness.

Other industries that consume significant amounts of steel include machinery and equipment manufacturing, shipbuilding, and energy (including oil and gas, renewable energy, and power generation).

Steel is vital for many industries — with its unique combination of properties, its versatility, and strength, this material is an essential component for countless products and structures worldwide for many years to come.

Sustainability for the Future

The steel industry has made significant contributions to global sustainability in recent years —both in terms of reducing its environmental impact and promoting sustainable practices across the supply chain.

Today, many steel companies have set ambitious targets to reduce their carbon emissions, including adopting new technologies like carbon capture and storage (CCS), using renewable energy sources, and increasing energy efficiency.

And, because the material is highly recyclable, American metal processors have made significant strides in promoting recycling and the circular economy. According to the World Steel Association, the global recycling rate for steel is over 90%, making it one of the most recycled materials in the world — reducing waste and conserving natural resources.

The steel industry is also committed to promoting social responsibility across its supply chain, including promoting fair labor practices and respecting human rights. Many steel companies have implemented strict social responsibility standards and participate in third-party audits and certifications to ensure compliance.

The Leading American Steel Processor: National Material Company

Like steel’s properties, we at the National Material Company pride ourselves as one of the most versatile, competitive, and sustainable American metal processors. Our wide array of steel processing capabilities, supply chain, and service makes us the perfect partner for your design and engineering needs. Proud to be ISO-9002 certified, and uncompromising in its employees’ safety standards, NMC is a company that leads the way through efficiency, innovation, and performance.

About National Material L.P.

National Material Company is a part of the National Material Limited Partnership steel division — one of the largest independent steel service centers in the United States. NMLP operates 16 steel service centers and processing facilities in the United States, Canada, and Mexico that ship over 2,000,000 tons of steel annually. NMC operates ten of these steel processing facilities and service centers located in the U.S. and Mexico and these locations are a key advantage for our customers in terms of logistics and cost.

Please visit our website at nationalmaterial.com, call us at (U.S.) 847-806-7200, or email us at nmcquotes@nmlp.com to discuss how we can be of service.