What’s the material that is on the forefront of innovation in the automobile industry? If you guessed aluminum or composite steels, you guessed wrong. When it comes to increasing fuel efficiency, quality, affordability, and durability, no material has made more of a difference than Advanced High-Strength Steel (AHSS) and Ultra High Strength Steel (UHSS).

In this and future communications we will begin sharing information about these products.

Advanced High-Strength Steel refers to a new generation of steel that provides high-strength (up to 2,000 MPa) and durability while maintaining formability that is crucial to the manufacturing process.

The primary AHSS grades are produced on high tech Continuous Annealing Lines that provide very high heat followed by a rapid controlled cooling rate of the austenite phase. Further controlled heating and cooling can take place depending on the desired properties.

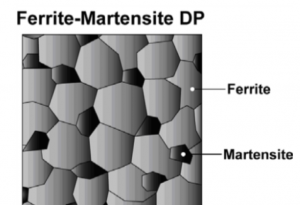

The difference is this production process and finished microstructure of the steel. Where conventional Low Carbon thru HSLA steel grades exhibit a nearly 100% Ferrite microstructure, AHSS / UHSS steels will exhibit a variety of different microstructures depending on the grade.

The primary types of materials being utilized are Dual Phase, Complex Phase/Multi Phase, Trip, Martensite and Press Hardenable Steel.

Dual Phase Steel

Ferrite-Martensite dual-phase steel is a low-to-medium carbon material with between 5-50% volume fractional martensite islands that are dispersed in a soft ferrite matrix. In addition to martensite, bainite and retained austenite components can also exist; these are normally produced when improved edge stretch formability is desired.

Ferrite-Martensite dual-phase steel is a low-to-medium carbon material with between 5-50% volume fractional martensite islands that are dispersed in a soft ferrite matrix. In addition to martensite, bainite and retained austenite components can also exist; these are normally produced when improved edge stretch formability is desired.

These variations in microstructure give dual-phase steels a wide spectrum of strength and ductility. DP steels are known to be capable of absorbing large amounts of energy. Combined with a low cost of production, these properties make DP steels highly desirable for automotive applications.

Dual-phase steels can be produced as both hot rolled and cold rolled based material. When Hot Rolled, the rolling temperature and cooling process on the Hot Strip Mill is carefully controlled to produce the ferrite-martensite structure from austenite. When Cold Rolled, the properties are developed on Continuous Annealing lines where there is even greater control over thermal treatment.

Automotive parts that currently use DP steels including but not limited to Crossmembers, Pillars, Roof Rails, Frame Extensions, Shock Towers, Crush Cans and Wheels.

Complex Phase Steel

Complex Phase steels gain their strength through extremely fine grain size and micro structure containing small amounts of martensite, pearlite and retained austenite embedded in a ferrite-bainite matrix. High grain refinement is achieved by precipitation of micro alloying elements such as Nb, Ti or V or retarded recrystallization.

CP steels have a higher minimum yield strength in comparison with dual phase steels of identical tensile strengths of 800 Mpa and greater. When compared to DP steels, CP steels have a much higher yield strength to tensile strength ratio.

Complex Phase steel is being produced as both hot-rolled and cold-rolled which can be hot dipped galvanized for corrosion protection. Hot-rolled products are available in the higher thickness ranges needed to produce structural type parts.

Press-Hardened Steel

Press Hardened Steel or Hot Formed Steels undergo a unique manufacturing process where the steel is heated to a minimum temperature of 850*C then formed to a final shape in water cooled dies that control the rates of cooling / quench to insure desired properties are met. The high temperature combined with rapid cooling transforms the microstructure to nearly 100% Martensite and very high finished tensile strengths up to 2000 Mpa. This process is commonly referred to as “Hot Stamping”. The finished product qualifies as advanced high-strength steel, and is three times as stable as the material was prior to undergoing the process. It’s strength-to-weight ratio is also vastly increased.

The implementation of press hardening applications and the utilization of hardened steels are promising alternatives for optimizing part geometries with complex shapes with no spring back issues. The Hot Forming process allows for the formation of shapes that cannot be cold stamped with Ultra High Strength steels.

The unique properties of this material combine both complexity and strength – and components made with press-hardened steel can accomplish in one piece what would usually require heavier, thicker parts that are welded together.

TRIP Steels

The microstructure of TRIP steels consists of at least five-volume percent of retained austenite, which is embedded in a primary ferrite matrix. The microstructure also contains hard phases like bainite and martensite in varying amounts.

TRIP steels are notable due to the higher carbon content than other members of the AHSS family, such as dual phase steels. They typically require the use of an isothermal hold at an intermediate temperature, which produces some bainite. Silicon and aluminum are added in order to both accelerate the ferrite and bainite formation process, as well as avoiding carbide buildup in the bainite region of the material.

Greater silicon, aluminum, and carbon content of TRIP steels result in large fractions of retained austenite in the material’s final microstructure. The increased carbon content also stabilizes the retained austenite phase below the usual ambient temperature.

As the technology continues to develop, the applications for AHSS in automobiles continue to expand. Crash safety with advanced high-strength steels continues to increase; as well as fuel economy, increased engine performance, and top speeds, which are a result of the reduced weight. Additionally, its cost effectiveness makes it an attractive material for structure parts, as well as bumper systems, seating, doors, and other safety parts.

Beyond the automotive industry, the following industries also stand to benefit with the development of advanced high-strength steels.

- Rail transport

- Energy

- Infrastructure

- Shipbuilding

- Aerospace

National Material recently upgraded their facilities with a Red Bud 72” (1830mm) wide slitting line with in-line leveling that has a thickness range of .012” – .250” and is capable of slitting grades up to 250,000 psi (1725 MPa) – an upgrade that was made with servicing the advanced high-strength steel market in mind.

About National Material L.P. – With more than 3,000 employees from a multinational portfolio of companies, NMLP provides engineered metal products, which include aluminum extrusion and stainless steel rolled product companies, to automotive, aerospace, construction, defense, electrical, and industrial markets.

Visit National Material: https://www.nationalmaterial.com or call (U.S.) 847-806-7200, Diana Pulido

https://www.worldautosteel.org/steel-basics/automotive-steel-definitions/