The Differences Between Hot and Cold Rolled Steel

When approaching your project, it is crucial to know the type of steel that is best suited for your needs. Different types of steel manufacturing can produce material that performs better for the specific applications. The hot and cold rolled steel manufacturing methods specifically have a great effect on the overall performance of the steel.

Prior knowledge of distinctions between the two methods can help your company save on time, raw material cost, and additional processing. This article aims to explain the differences between hot and cold rolled steel and discuss the advantages (and limitations) of each.

NOTE: Hot-rolling and cold-rolling should not be mistaken for different grades of steel. Steels of different grades can be produced as hot-rolled or cold-rolled.

HOT-ROLLED STEEL

Hot-rolling refers to a mill process in which you roll the steel at a temperature above its recrystallization temperature; a heat that typically exceeds 1000° F.

When steel is heated past its recrystallization point, it becomes more malleable and can be properly formed and shaped. It also allows for the ability to produce larger quantities of steel. The steel is then cooled at room temperature, which “normalizes” it, eliminating the worry for stresses in the material arising when quenching or work-hardening.

When the steel cools off, it will shrink non-uniformly, which gives slightly less control on the overall size and shape of a finished hot-rolled product.

Hot-rolled steel typically has a scaly surface finish. For situations in which the appearance of the material is a concern, the scales can be removed by several techniques: pickling, grinding, or sand-blasting.

These properties make hot-rolled steel most suitable for structural components and other applications where incredibly precise shapes and tolerances are of less importance, such as:

- Railroad tracks

- I-beams

- Agricultural equipment

- Sheet metal

- Automotive frames

COLD-ROLLED STEEL

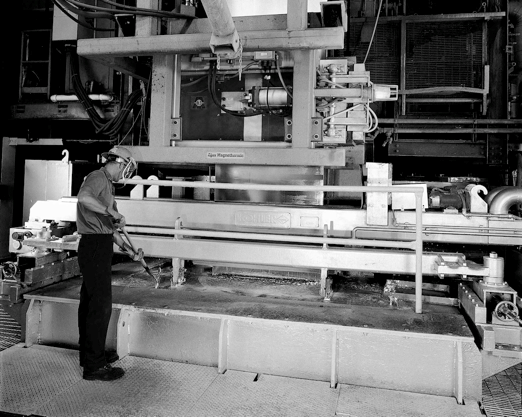

As you might suspect, the manufacturing process behind cold-rolled steel is a bit different. Despite the name, this process refers to steel that is pressed with the pressure of a roller at room temperature.

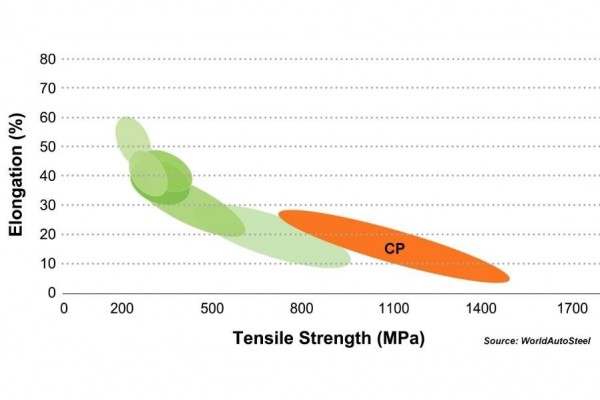

Compared to hot-rolled steel, cold-rolled steel has a nearly 20% increase in strength through the use of strain hardening. It’s through a series of breakdown, semi-finishing, sizing, semi-roughing, roughing, and finishing that cold-rolled steel shapes can be created.

Cold-rolling steel allows for the creation of very precise shapes. Since the process is performed at room temperature, the steel will not shrink as it cools, as it does in the hot-rolled process.

The exterior finish of cold-rolled steel is very desirable when aesthetics and visual appeal are a priority in your project.

However, the applications of cold-rolled steel are somewhat limited to a couple of shapes – square, round, flat, and variations thereof.

Typical […]