How Metal Manufacturing Supports the Agricultural Industry

When you think of farming what’s the first thing that comes to mind? Rows of crops? Animals in a barn? Bails of hay perhaps? All these things are likely be found on farms but what is often forgotten about is the equipment that makes all these elements possible. From feeding pails to tractors to silos, the metal manufacturing industry is intrinsically linked to the agricultural industry. Modern farming is extremely efficient, mostly thanks to the industrialized nature of the facilities filled with factory-like machines. We will explore how the steel industry supports the agriculture and farming industry, the advantages it provides, and how National Material Company is prepared to supply the necessary materials to agricultural OEMS.

How is steel used in the agriculture and farming industry?

The agriculture industry is becoming increasingly competitive because of the efficiency of the operations. With higher quality metals, agricultural machine manufacturers create more reliable, efficient machines that translate into better farming. Steel is found in a variety of farming equipment including:

- Storage facilities like barns and silos

- Harvesting equipment like tractors, cotton pickers, hay balers, etc.

- Greenhouses

- Livestock management equipment like fencing, feeding pails, milk machines, etc.

- General operation equipment like forklifts, watering systems, drains, etc.

What’s the advantage of using steel in agriculture and farming?

Agriculture and farming is dirty business; filled with heat, dirt, chemicals, and various harsh elements from the great outdoors. This means that farming equipment is susceptible to being easily corroded, creating a demand for tougher, resilient equipment. This is where steel comes in. Hot-dip galvanized steel provides corrosion protection that can often last for decades, even when exposed to the harsh environment of farming.

Stainless steel is also utilized for its surface properties. With a standard, shiny finish, it makes it particularly easy to clean. Also, in applications like dairy farming, the smooth finish is important because of the need to maintain microbiological quality in the raw milk.

What can NMC provide for agricultural and farming equipment companies?

As an increasingly competitive industry, having the best source for metal fabrication is critical for any agricultural OEM. National Material Company is capable of providing a wide variety of metals including galvanized steel and advanced high-strength steel, as well as steel processing like blanking and pickling, to these manufacturers.

Our experienced team can provide an array of materials with good design, maximum corrosion resistance, and do so with accelerated customer service. Whether you’re looking to build small parts for a milking machine, or large sheets of metal for a grain silo, NMC can serve you. With our ISO- 9002 certification, you have reassurance that your farming equipment is produced with the highest quality standards.

About National Material L.P. – Since its founding in 1964, National Material Limited Partnership has grown to over 30 business units and is now one of the largest suppliers of steel in America. The National Material group of industrial businesses consists of the Steel Group, Stainless and Alloys Group, Raw Material Trading Group, Aluminum Group, and Related Operations.

If you believe your company can benefit […]

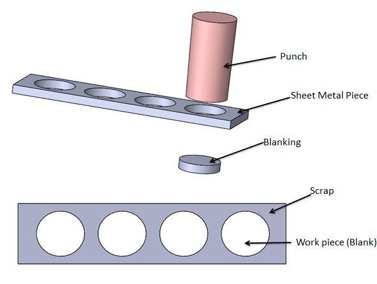

Press Blanking machinery can typically process material up to 72 inches (1828mm) wide and .250 inches (6.35mm) thick from coils up to 80,000 lbs. Typically multiple sheets are blanked in a single operation and the blanked parts will require secondary finishing to smooth out burrs along the bottom edge.

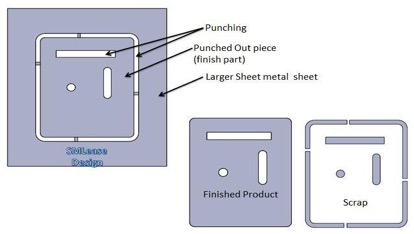

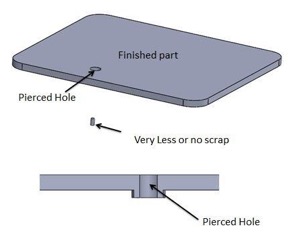

Press Blanking machinery can typically process material up to 72 inches (1828mm) wide and .250 inches (6.35mm) thick from coils up to 80,000 lbs. Typically multiple sheets are blanked in a single operation and the blanked parts will require secondary finishing to smooth out burrs along the bottom edge. Another similar process is piercing, in which a punch operation cuts a hole by tearing operation from a final piece of sheet metal. This is process is considered a blanking operation.

Another similar process is piercing, in which a punch operation cuts a hole by tearing operation from a final piece of sheet metal. This is process is considered a blanking operation.

WHAT IS STEEL PICKLING?

WHAT IS STEEL PICKLING?