In today’s global metals industry, sustainable supply chains in metals are no longer a lofty aspiration — they are a business imperative. Regulatory agencies, customers, and financial stakeholders are increasingly pressuring companies to reduce their carbon footprints and decarbonize supply chains. But how do organizations in metals and manufacturing, such as National Material Company (NMC) and Greenway Steel lead the way in this transformation? The answer to sustainable supply chain in metals and manufacturing result from transparency.

Transparency is the cornerstone of sustainable supply chains in metals, enabling companies to accurately track carbon emissions in alignment with the GHG (greenhouse gas) Protocol. This data-driven approach empowers businesses to meet their sustainability goals while ensuring accountability. By openly sharing information about raw material sources, production processes, and logistics, companies can reduce environmental impact and foster trust.

Addressing the Challenge: Transparency and Accountability

Calculating the carbon footprint of a global steel and aluminum supply chain is no small feat. The GHG Protocol requires companies to calculate direct and indirect emissions, known as scopes 1, 2, and 3. Scope 3 emissions, which encompass upstream raw material extraction, downstream transportation, and product use, pose the greatest challenge due to their complexity and breadth. Yet, identifying and managing these emissions is critical — not only to meet regulatory requirements but also to satisfy growing consumer demand for greener, more sustainable products.

As a recognized leader in steel processing and metal supply chain management, National Material Company (NMC) faced this challenge head-on. A key automotive customer sought to understand its entire supply chain’s carbon footprint. Given the global nature of the supply chain — with steel and aluminum parts sourced and processed worldwide — NMC collaborated with Greenway Steel to deliver a transparent, data-driven solution.

Case Study: NMC and Greenway Steel’s Collaborative Approach

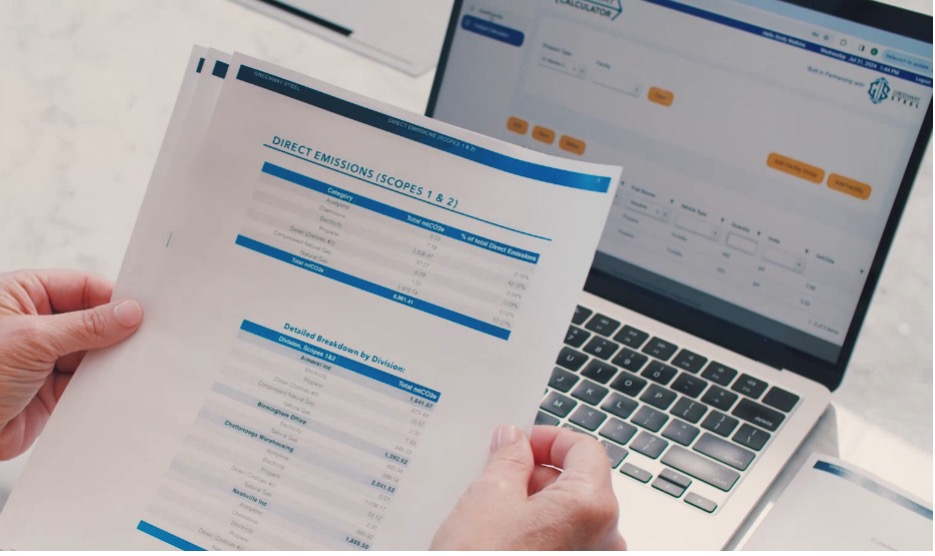

NMC and Greenway Steel joined forces to tackle the challenge of calculating a complete value chain carbon footprint. By leveraging Greenway Steel’s proprietary Greenway Calculator and NMC’s expertise in steel processing, they systematically assessed the carbon intensity at each stage of the supply chain.

The first step involved calculating direct emissions, scopes 1 and 2, associated with the energy consumed during metal processing. By determining the energy intensity of their operations, NMC could accurately estimate the emissions generated per unit of steel processed. Using standard emission factors, they could then calculate the direct carbon footprint of their steel production.

Image Attribution: https://greenwaysteel.com/

Next, NMC turned its focus to the more complex scope 3 emissions, which encompass indirect emissions from the upstream production of raw materials (embedded carbon) and downstream logistics. These emissions represent the majority of carbon output in the global steel supply chain, with a significant portion stemming from base metals’ production. Understanding and managing these embedded emissions is essential for reducing the overall carbon footprint.

Using Greenway’s advanced carbon management tools, NMC successfully tracked scope 3 emissions across its supply chain. This enabled them to provide their automotive manufacturing customer with a transparent, data-driven view of the entire process — reinforcing NMC’s commitment to building sustainable supply chains in metals.

Simplifying Carbon Footprint Calculations with Technology

Calculating the carbon footprint of a metals and manufacturing supply chain can be a complex and time-intensive process. However, NMC’s collaboration with Greenway Steel has revolutionized this task. Leveraging the innovative Greenway Calculator, NMC streamlined the calculation of its supply chain’s carbon footprint while ensuring compliance with the GHG Protocol.

The Greenway Calculator takes a systematic approach, focusing on emissions intensity — the ratio of emissions to the volume of metals processed — rather than revenue, which can fluctuate with market volatility. This method is particularly impactful in the metals industry, where commodity prices often mask the true environmental impact of production processes.

By focusing on energy consumption, embedded emissions, and logistics, NMC and Greenway Steel could create a transparent and comprehensive view of the entire supply chain’s carbon footprint. This transparency allows for better decision-making, enabling NMC to identify areas for improvement, reduce emissions, and offer their customers a greener supply chain.

Image Attribution: https://greenwaysteel.com/wp-content/uploads/2024/06/09_GS-Article.pdf

The Importance of Transparency in Supply Chain Sustainability

Transparency isn’t just about meeting regulatory requirements — it’s about building trust with customers, stakeholders, and regulators. For companies like National Material Company (NMC), offering a clear view into their sustainable supply chains in metals gives customers the confidence to make informed decisions about the environmental impact of their products.

This approach also has financial benefits. Companies can reduce their carbon footprint and operational costs by identifying inefficiencies in the supply chain and optimizing logistics and production processes. Additionally, by leading the way in transparency, NMC sets itself apart as a forward-thinking company that meets the growing demand for sustainable practices in the metals industry.

National Material Company’s Commitment to a Sustainable Future

NMC’s partnership with Greenway Steel showcases how transparency in supply chain management can drive sustainability in the global metals industry. By utilizing cutting-edge technology, like the Greenway Calculator, and adhering to standards such as the GHG Protocol, NMC has set a new benchmark for sustainable steel and metal supply chains.

For companies looking to reduce their carbon footprint, collaboration with experts like NMC and Greenway Steel provides a clear path toward a greener, more sustainable future. Learn more about NMC’s innovative solutions for supply chain management by visiting their page and here to learn about Greenway Steel’s expertise in carbon accounting. Read more about it in Greenway Steel’s white paper.

About National Material Company

Founded in 1964, NMC is a leader in steel processing and supply chain management, offering innovative solutions to industries worldwide. NMC specializes in processing and distributing steel and other metals for various markets, including automotive, construction, and manufacturing. With decades of expertise, NMC is committed to delivering quality, efficiency, and sustainability across all aspects of the metal supply chain. By prioritizing transparency and leveraging advanced technologies, NMC helps businesses optimize their supply chains while meeting global sustainability standards.