How Metal Processing Impacts Key Sectors

Main Takeaways

- Metal processing impacts key sectors such as aerospace, automotive, construction, and renewable energy, driving innovation and efficiency.

- Lightweight metals like aluminum alloys and AHSS enhance fuel efficiency, structural integrity, and performance in industries like EV production and aerospace engineering.

- Precision steel slitting, galvanized steel processing, and aluminum extrusion are crucial for manufacturing durable, high-performance components across multiple sectors.

- National Material Company (NMC) provides tailored metal processing solutions, leveraging cutting-edge expertise, supply chain efficiency, and sustainability initiatives. Partnering with NMC ensures access to industry-leading capabilities in steel processing, aluminum extrusion, and supply chain management to support your next project.

For engineers, procurement specialists, and industry leaders, selecting the right materials isn’t just about meeting specifications, it’s about driving innovation and solving real-world challenges. Whether you’re designing fuel-efficient aircraft, lightweight electric vehicles, durable infrastructure, or sustainable solar energy systems, one thing remains clear: metal processing impacts key sectors in profound ways.

From advanced high-strength steels (AHSS) to aluminum extrusion, modern metal processing techniques are shaping the future of aerospace, automotive, construction, and renewable energy. This article explores practical applications, industry advancements, and emerging trends like green steel production, providing insight into how these innovations can drive efficiency and sustainability.

Lightweight Metals for Soaring Innovations

The aerospace industry relies on lightweight yet durable materials to optimize performance and efficiency. Aluminum alloys, titanium, and specialized steels are essential for reducing aircraft weight while maintaining structural integrity and safety. As metal processing impacts key sectors like aerospace, advancements in material science and manufacturing techniques continue to push the boundaries of innovation.

For example, aluminum extrusion techniques allow manufacturers to create complex shapes that optimize aerodynamics and fuel efficiency. According to Taber Extrusions, alloys in aerospace applications can withstand extreme temperatures and pressures, ensuring safety at 35,000 feet.

One fascinating insight is the growing use of additive manufacturing (3D printing) in aerospace metal processing. By layering metals like titanium and stainless steel, engineers can produce intricate components faster and with less waste than traditional methods. This shift also supports sustainability initiatives, demonstrating how metal processing impacts key sectors by minimizing material consumption while enhancing precision and performance.

Galvanized steel also finds its place in aerospace infrastructure, such as hangars and maintenance facilities. Its corrosion-resistant properties ensure longevity even in harsh environments. These innovations underscore how metal processing impacts key sectors by enabling safer, more efficient air travel.

Paving the Way for Electric Vehicles

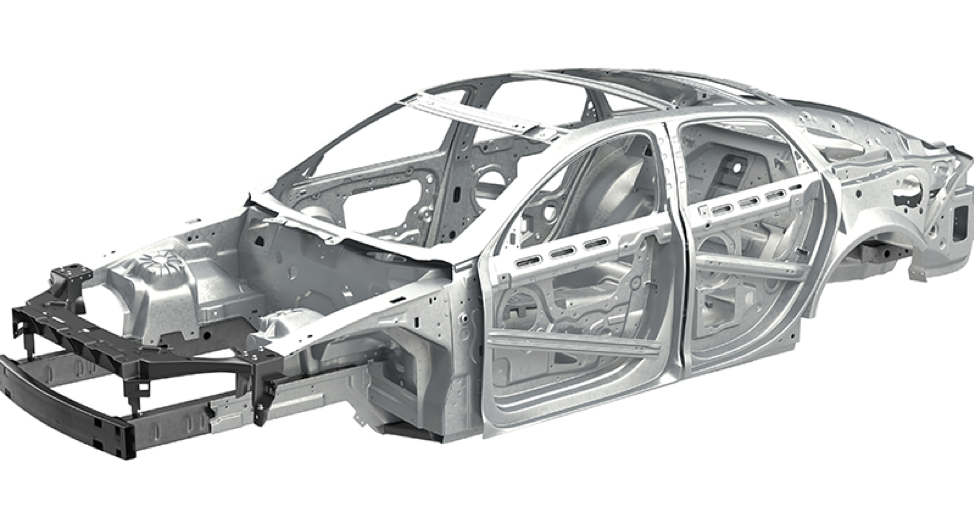

As the automotive industry accelerates its shift toward electric vehicles (EVs), the need for advanced metal processing is more critical than ever. Metal processing impacts key sectors like automotive manufacturing by ensuring the production of strong yet lightweight materials essential for EV design and performance.

Steel processing remains essential for producing robust frames, while aluminum processing provides lightweight alternatives for battery enclosures and body panels. Advanced high-strength steel (AHSS) is particularly noteworthy — it delivers exceptional crash […]