Steel Service Spotlight: National Material of Mexico

“Alone, we can do so little; together, we can do so much.”

–Helen Keller

National Material Company (NMC) has maintained continuity since its inception – never changing ownership or strategic focus. This has allowed NMC to become an industry leading company. It’s true that this longevity gives NMC a competitive edge in the steel service industry, but it’s also true that NMC’s leadership has not only been built across time, but across cultural boundaries. National Material of Mexico (NMM), a global partner in Mexico that not only leads the Mexican steel service but has recently undergone an exciting expansion of their facilities.

About National Material of Mexico

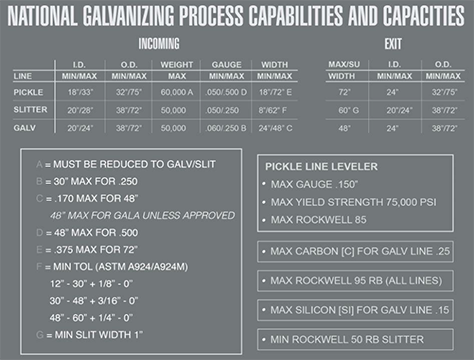

Both NMC and NMM are part of the National Material Limited Partnership (NMLP) steel division, which is one of the largest independent steel service centers in the United States. NMLP operates 16 steel service centers and processing facilities in North America and ships over 2,000,000 tons of steel annually.

National Material of Mexico is one of the largest Steel Service Centers in Mexico, serving the automotive, HVAC, home appliance, motor and transformer manufacturers in Mexico. A large portion of NMM’s success lies in its supply of ultra-light and ultra-strong Advanced High Strength Steel (AHSS) to the Mexican automotive business.

It provides all the AHSS grades as well as other material processing services with hot rolled, cold rolled, grain-oriented and non-oriented electrical steel, galvanized, galvannealed, aluminized, prepainted and other coated metals.

Like its northern partner, NMC, National Material of Mexico’s premier standing in the Mexican steel service industry relies not only on its efficiency at the plants, but also on a timely supply of all materials to clients.

With the National Material Limited Partnership as a constant support system, the companies create synergies and partnership that streamline processes with tangible benefits to the clients.

NMM locations and joint-venture locations include facilities in:

- Monterrey

- Hermosillo

- San Jose Iturbide

- Puebla

- San Luis Potosi

- Celaya

- Aguascalientes

With these strategically placed service centers, NMM aims at a “Just-in-Time philosophy” for direct sales and toll processing.

Expansion & The Future of NMM

In 2017, National Material Company announced the expansion of their plants in Mexico for a twofold reason: first, to meet increased demand and second, to focus on the futuristic Advanced High Strength Steel that is going into cars. As VP General Manager Carl Grobien explains:

“We opened up this facility in 1997 with one slitter. Now, we have two slitters, one for electrical steel and one for carbon steel. After so many years, the first slitter is more than 100% full and with the new generation steel, AHSS or Advanced High Strength Steel, going in to automobiles, our steel now goes into […]