Processing Steel in the U.S. – Metal Forming 101

Metal forming is a process vital in the US steel processing industry. Renowned for its capacity to mold complex shapes and structures, it’s a process embraced by steel processors throughout North America for its capability to generate a wide array of essential products, from precision automotive parts to critical aerospace components.

Metal forming requires skilled professionals and advanced machinery, which is where steel service centers come in. These centers are the go-to source for metal processing, forming, and distribution, providing essential services that help transform raw materials into finished products.

What is Metal Forming?

Have you ever wondered how metals manufacturers create various shapes and sizes of metal parts? It’s thanks to the fascinating process of metal forming: the art of shaping a piece of metal into any desired shape. Various methods are involved in this process, from roll forming and bending to extrusion and forging.

The best part about metal forming is its efficiency and accuracy. With this technique, manufacturers can create large, sturdy metal parts with high precision. And that’s why it has become an indispensable part of the manufacturing industry today. Next time you observe a metal part, remember it was made using a specific process.

Metal Forming Process: The Basics

Metal forming is a captivating process that encompasses a diverse array of production techniques. From forging and casting to rolling and bending, there are countless ways to transform raw metal stock into a finished item. Regardless of the technique, manufacturers aim to create high-quality products that meet customers’ needs. So, whether you’re a metalworking expert or just curious about the industry, metal forming is worth learning more about!

Cold Working Process

In the cold working process, one applies force to reshape metal, changing its shape without adding or removing any material. This process can achieve the desired shape of the metal at room temperature.

Heat Treated Process

Metals can be changed in many ways to make them more robust, flexible, and wear-resistant. One way to do this is by heat treatment, a process of altering the physical or chemical properties of a metal through the use of heating or chilling, normally with extreme temperatures, to achieve the desired result or appearance. Heat treatment is a common method used by manufacturers to give metals intricate shapes that are impossible to achieve through simple bending. It can also make steel more flexible and last longer.

Five distinct metal-forming processes:

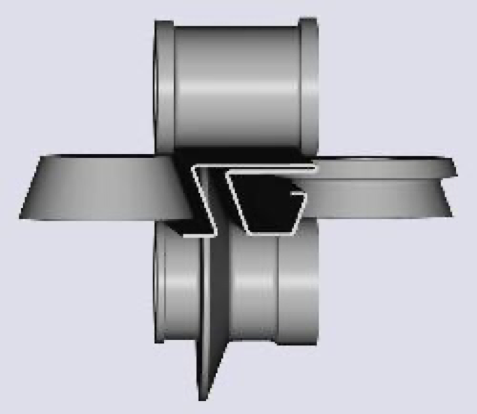

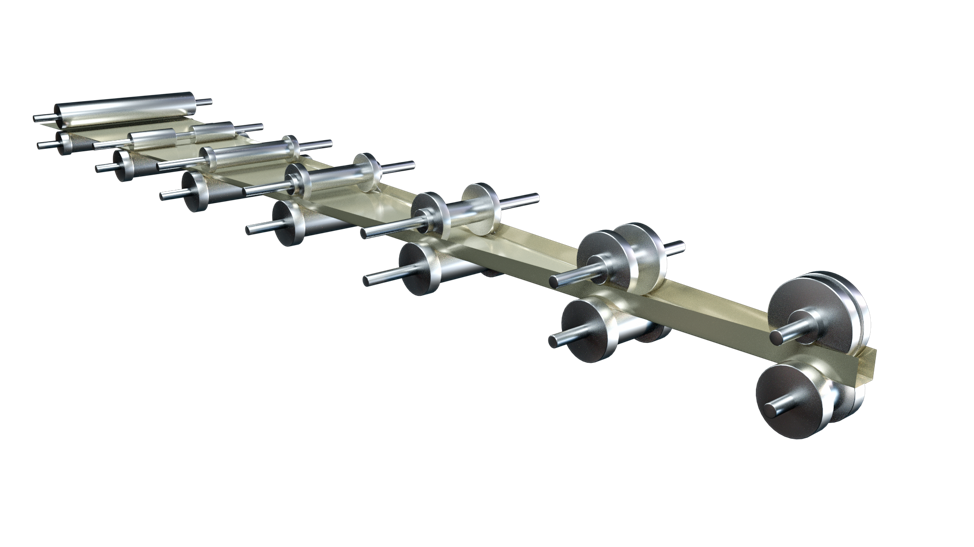

1. Roll Forming

Roll forming is a key manufacturing process that involves bending a long strip of metal, typically coiled steel, by passing it through consecutive sets of rolls. Each pair of rolls performs a part of the bend until the metal achieves the intended cross-sectional profile. This method is versatile, allowing for the creation of various shapes and sizes at room temperature.

The process allows for manipulation of metals to enhance their physical or mechanical properties, achieving […]