The Role of the Steel Service Center for OEMs

For companies that make original equipment (OEMs), finding the best materials is more than just important — it gives them an edge over others. Steel service centers for OEMs, like National Material Company (NMC), are essential. They ensure OEMs get the best steel that fits their needs, helping them work better, make more profit, and improve operations.

Steel service centers like NMC bridge the gap between steel mills and OEMs, offering precision cutting, slitting, and processing. This partnership allows OEMs to focus on core activities while trusting service centers for consistent, ready-to-use materials. This blog explores the role of a steel service center for OEMs, highlighting how NMC streamlines operations, improves product quality, and reduces costs.

What Does it Mean to Be an Original Equipment Manufacturer (OEM)?

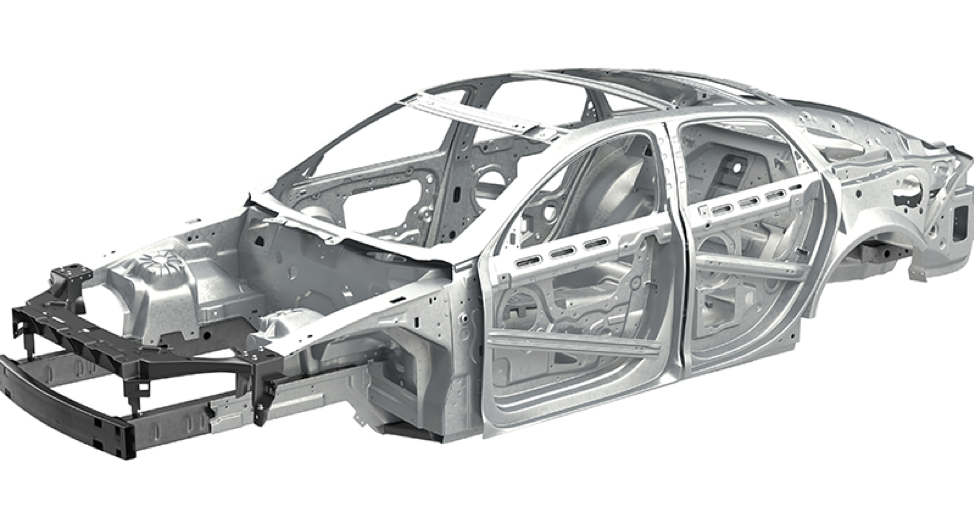

An original equipment manufacturer (OEM) produces parts or components that another company incorporates into its products, which are then sold under that company’s brand. OEMs are common in industries such as automotive and computing.

For example, a branded laptop might source processors or memory modules from an OEM. OEMs typically produce parts for value-added resellers (VARs), focusing on manufacturing rather than the final product design.

Historically, OEMs have sold primarily to other businesses rather than directly to consumers. However, some OEMs now also sell parts directly for consumer repairs.

What are Alternatives to OEM Parts?

Ensuring a steady supply of cost-effective spare parts is critical for any manufacturing operation. Managing spare parts inventory represents a significant and inevitable cost for companies utilizing industrial machinery.

While OEMs might be the go-to for all necessary spares and components, the market offers other alternatives such as OE, ODM, and aftermarket parts.

OE Components:

Produced by a different company but meet the same factory standards as OEM parts.

ODM (Original Design Manufacturer):

An original design manufacturer (ODM) is distinct from an OEM. ODMs create products based on a client’s specifications, which the client then sells under their brand. ODMs have less design leeway than OEMs because they work within client-provided specifications. However, this model benefits from reduced R&D costs, lowering consumer prices.

Aftermarket:

While OEMs produce original equipment, aftermarket manufacturers create products compatible with OEM parts. In essence, aftermarket parts are non-original replacements made by companies — either local or international — without the authorization of the original manufacturers. These parts are often less expensive but may not guarantee the same level of performance as OEM products.

What are the Advantages of Purchasing OEM Products?

• Superior quality: OEM products, crafted by the original creators, offer unmatched quality compared to alternatives. The premium price reflects their superior construction.

• Longevity: Built to last, OEM products, such as spare tires, ensure the material’s quality and durability.

• Extended service life: OEM components generally have a longer service life […]