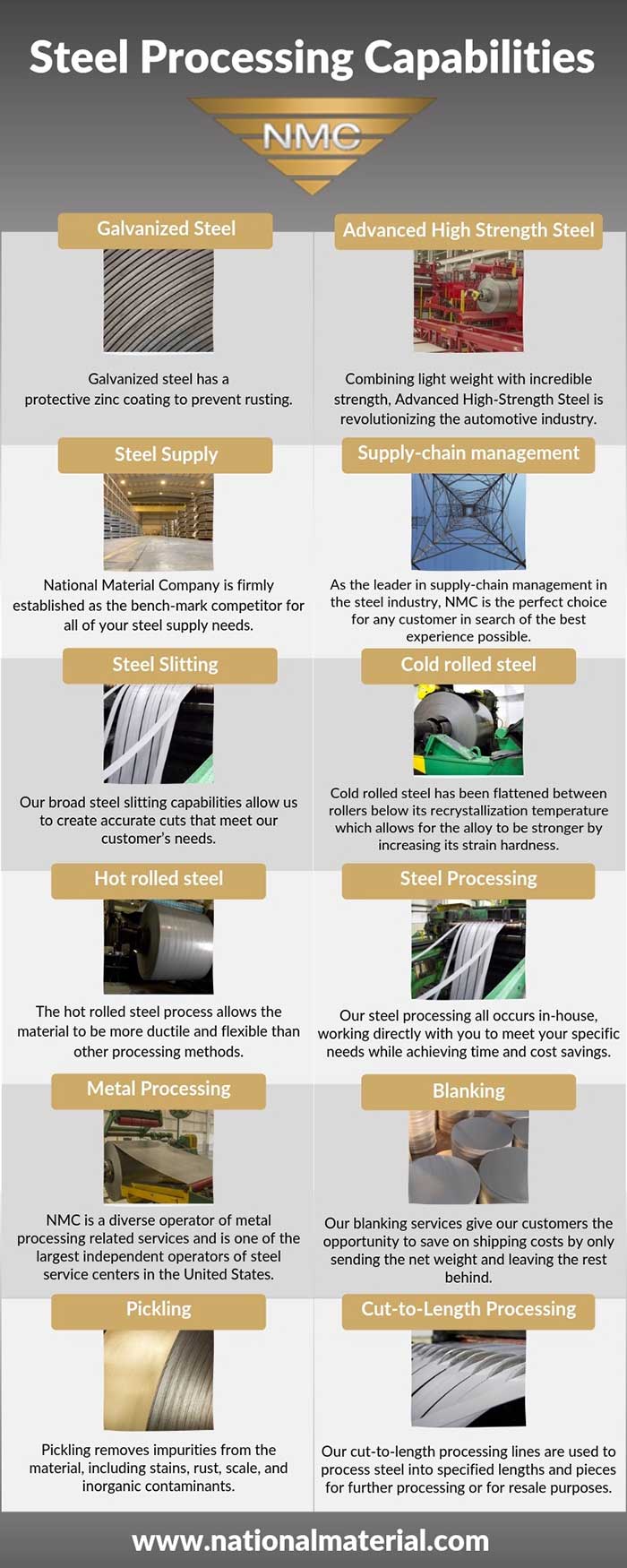

NMC’s Steel Processing Capabilities

As the leader in steel processing capabilities, supply chain management, and inventory control, NMC is the perfect choice for any customer in search of the best experience possible. A dedicated work force, state-of-the-art slitters, cut-to-length lines and warehouse storage capabilities make NMC the premiere steel manufacturing company in North America. Locations throughout The United States and Mexico offer a logistic advantage resulting in a more efficient service to conserve our customer’s most valuable resource: cost.

WHAT IS STEEL PICKLING?

WHAT IS STEEL PICKLING?