Choosing the right steel product is imperative, and considerations such as “galvanized steel,” “pre-galvanized,” and “hot-dipped galvanized” are part of the decision-making process.

This guide is intended to break down the key differences between pre-gal and other galvanized options, including hot dipping, electrogalvanizing, and galvannealing. Our goal is to extend our expertise – sharing benefits, uses, and when it’s better than other galvanized metals.

Pre-Galvanized Steel: What You Need to Know

What gives a steel sheet a shiny, almost silvery finish? The power of galvanization. It’s a process where steel gets a zinc coating which protects the steel from its biggest enemy—rust. But in the world of galvanized steel, there are different types.

Inside the steel processing plant, steel is zinc-plated early on before it’s cut. This “in-line galvanizing” process creates an even zinc layer, making pre-galv a great choice for applications that expose most of the surface.

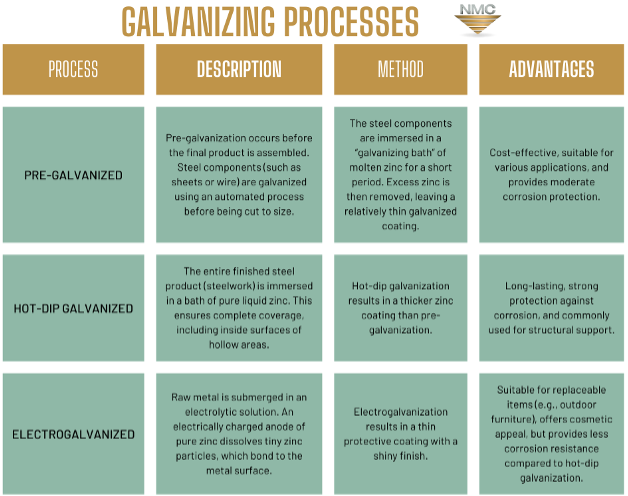

Here’s how pre-gal stacks up against its familiar competitors:

Hot-Dipped Galvanized — This tough competitor gets dipped in molten zinc. This results in a thicker coating, which is ideal for harsh places. But, if we expose cut edges, we must make the process more suitable for complex shapes.

Electrogalvanized — This uses electricity to create a thin, super-uniform zinc layer. It is great for small parts and tight spaces, but it might not hold up well in areas with a lot of wear and tear.

When Does Pre-Galvanized Steel Shine Brightest?

Manufacturers use pre-galv steel in many applications. They use it for its mix of low cost, good rust resistance, and formability. Here are some of the most common uses:

Construction

Roofing and other building applications. Manufacturers use it to make roofing sheets, gutters, flashing, and downpipes. It offers a lightweight, durable, and weather-resistant solution for roofs.

Furniture

Pre-galvanized steel is a great material for constructing furniture due to its high-quality 3D designs, accurate steel designs, and affordability. It may also utilize nano-environmental technology, which provides additional benefits. This material is commonly used for making outdoor furniture, such as lounge sets and benches, due to its excellent resistance to rust and corrosion, making it ideal for outdoor usage.

Appliance Parts

Many appliance components such as washing machine tubs, dryer parts, and refrigerator components can all use pre-galvanized steel. Manufacturers choose it for its rust resistance and formability.

Automotive Parts

Pre-galvanized steel is also used in vehicle manufacturing. Manufacturers can make fender panels and other parts from it, which fights rust on parts exposed to the elements.

Galvanizing vs. Galvannealing

Now that we’ve explored the major points of pre-galvanized steel, you might be curious about other ways to add a zinc shield to steel. Let’s take a look into the world of galvanizing…

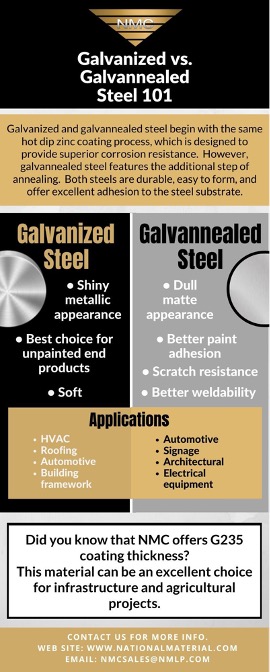

Think of galvannealing as a two-part origin story for steel. First, it goes through the familiar galvanizing process — a zinc bath dip to create a protective layer. But galvannealing adds an extra step called annealing. In this second step, the steel gets heated and cooled. This has a significant impact. The heat allows some of the iron from the steel to mix with the zinc coating, creating a brand-new zinc-iron alloy.

How does this compare to regular pre-galvanizing? Here’s a quick breakdown:

Pre-galvanized steel and its solid zinc shield is cost-effective and offers good corrosion resistance.

Galvannealed steel with its “extra step” makes the alloy harder and more scratch resistant. It also bonds better with paint and welding.

The trade-off is that galvannealed steel is a bit more expensive and can be less flexible than pre-gal. Therefore, the choice between them depends on your project’s needs.

National Material Company: Unparalleled Capabilities for Galvanized Steel Excellence

Choosing the right steel is crucial for the success of any project, which is why National Material Company (NMC) strives to be your one-stop shop for all steel needs. They offer a wide array of high-quality pre-galvanized steel sheets, available in various thicknesses and sizes to suit different applications.

More than just providing an extensive product catalog, NMC is committed to supporting informed decision-making. With in-house metallurgists and steel experts on hand, they have a wealth of knowledge and are ready to assist with any queries or provide the necessary support.

NMC’s dedication to galvanized steel extends far beyond pre-gal. NMC’s partner company, National Galvanizing aims to create a powerhouse of galvanized steel solutions. Their combined expertise allows them to offer many services in a 245,000-square-foot facility serving a wide array of industries including automotive, solar, heavy truck, agricultural, garage door hardware, and HVAC.

Imagine the efficiency of pickling, galvanizing, galvannealing, and even steel slitting—all under one roof. This simple approach ensures that NMC can respond to your changing project demands. A leader in steel supply chain expertise, NMC provides a one-stop shop for all your galvanized steel requirements.

Experience the NMC difference. Email National Material Company at nmcquotes@nmlp.com, call (U.S.) 847-806-7200, or contact their friendly sales team today. They’re eager to discuss your project needs. They’ll help you find the ideal pre-galvanized steel solution to bring your vision to life.

About National Material L.P.

National Material Limited Partnership (NMLP) has a rich history dating back to 1964. Over the years, it has become a powerhouse and one of America’s top steel suppliers. NMLP’s reach is global, serving many industries, from automotive giants to construction innovators.

NMLP doesn’t deliver steel—it delivers results. They commit to quality and service. This commitment has earned them the trust of top companies in many sectors. The roar of cars, the innovation of aerospace, the backbone of construction… NMLP provides the steel processing solutions that keep the world moving.

NMLP perpetually seeks new opportunities and develops cutting-edge products and services. This dedication to progress ensures they stay a leader in their core businesses. They bring over 60 years of expertise and value to their partners worldwide.